Research Achievements

The Institute has finished about 30 scientific research programs (such as National 863 Program, Natural Science Foundation of China, Jiangsu Provincial Technology Support Program, Jiangsu Provincial Key Technologies Research Programmed). Six of which have been awarded scientific and technical achievements prizes of provincial level. More than 100 academic papers have been published. More than 40 papers have been cited by the three distinguished indexes such as SCI, EI. 20 national patents have been held and applied. More than 10 books have been compiled and published.

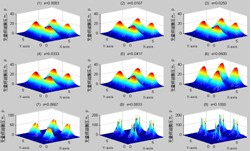

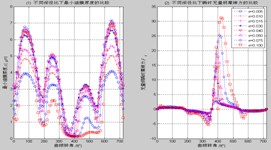

I. Tribology theory and micro-texture optimization designing of LST:

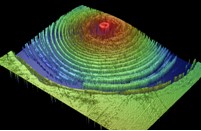

A lubrication model was developed for the piston ring and cylinder Liner with regular microstructure in the form of parabolic profile dimples. The influence of surface micro-geometry shape parameters on lubrication performance was obtained by solving the dimensionless Reynolds equation with modified multi-grid method. The results show that micro-holes through LST can efficiently produce hydrodynamic pressure.

Fig.1 Hydrodynamic pressure distribution of micro-holes

Fig.2 Change of oil film and friction in whole motion cycle of engine

II. Research on special LST equipment

The “single-pulse interval of the same point many times” method is adopted, which is a new method for laser micro-texturing. It combines motion control with Q-switch control to keep single laser pulse output during the processing time. The method can significantly reduce the negative thermal effects during laser processing.

Fig.3. LST machine with work piece rotation Fig.4. LST machine with laser head rotation

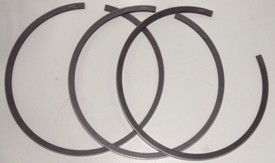

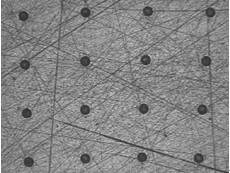

III. LST application in the key friction units of engine:

Laser surface texturing (LST) is an effective approach for improving the terminological properties of friction pairs. Experimental results indicate that it is practicable to apply single pulse interval laser honing technology to cylinder bore surface of diesel engine, based on Q switched diode-pumped solid-state (DPSS) No: YAG laser. Experiment on performances of engine bench scale test has been carried out. It is found that the characteristics of power, torque and fuel consumption keep stable, the oil consumption was reduced by 50% and the emission of combustion engines was reduced about 40%, comparing with traditional plateau honing technology.

Fig.5 .Laser micro-machining of cylinder Liner Fig.6. LST of cam shafts

Fig.7. LST cylinder Liner Fig.8. LST of piston rings

Fig.9.LST of mechanic seal Fig.10.Various LST components

Fig.11. Micro-holes with LST Fig.12. Micro-grooves with LST

Fig.13. 3-D profile of laser micro structuring

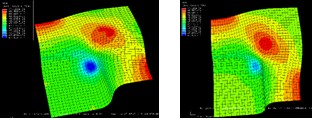

Fig.14. Processing simulation of LST die

Fig.15. Laser microstructure die

Fig.16. LST diesel engine bench scale test

Fig.17. LST gasoline engine bench scale test

Cooperation and Interchange

Academician of Chinese Academy of Sciences: Shi-zhu Wen and Yangtse Rive Scholar: Jian-bin Luo visiting and guiding our Institute. |