Name:Institute of Laser Technology, School of Mechanical Engineering, Jiangsu University

Tele:(86) 511 88797198

Fax:(86) 511 88797036

Research institutions with provincial or ministerial level:

Jiangsu Key Laboratory of Photonics Manufacturing Science and Technology

Key Laboratory of Laser Shock Processing for Machinery Industry

Researchers:11 Professors / Ph.D., 9 Professors and 8 Associate Professors

Research Achievements:

Published more than 500 papers, includedmore than 200 SCIpapers; Applied for more than 10international patents; Applied for more than 200 Chinese invention patents and among which more than 150 invention patents have been authorized; Won a first prize and a second prizeof national science and technology progress award, four first prizes of provincial/ministerial science and technology award, and seven second prizes of provincial/ministerialscience and technology award. A total of 25 million yuan has been received from various funds.

Main research directions:

Laser shock processing/laser peening technology and its industrial application

Laser precision cutting and welding technology

Laser micro machining and surface engineering technology

Laser cleaning technology and its application

Typical research equipment:

Nanosecond high power automatic laser shock processing system, fiber laser processing system, laser cleaning system, picosecond laser processing system, residual stress/ strain measurement system and so on, the total value of the equipment more than 15 million yuan

Parameters of Nd:YAG-GAIA laser

Nd:YAG-GAIA laser |

Operation Material |

Nd:YAG |

Frequency(HZ) |

1~5 |

Wavelength(nm) |

1064 |

Power Distribution |

Flat |

Pulse Power(J) |

<12 |

Spot Shape |

Circle |

Pulse Width(ns) |

<15 |

Focus Size(mm) |

Ф3~8 |

GAIA-Thales Laser and its controller

Laser path of GAIA-Thales laser and its external laser path

Main research contents:

1. Temporal and spatial propagation characteristics of laser induced plasma shock waves

Temporal and spatial propagation Shock wave loading model for

characteristics of laser shock waves laser shock processing

Propagation characteristics of laser Effect of repeated loading shockwave

shock wave in depth direction

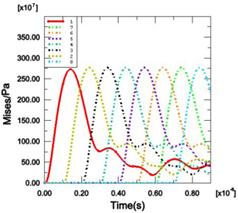

2.Numerical simulation of the propagation of laser shock wave

Distribution characteristics of residual stress at different time

3. Mechanism of high strain rate strengthening of materials under wave solid coupling

Schematic illustration showing micro-structural evolution of the top surface induced by different numbers of Laser shock processing impacts

Typical TEM images of the top surface subjected to different numbers of laser shock processing impacts

4.Experimental study on fatigue crack propagation of laser peening

Typical6061-T6CT samples subjected to differentlaser peeningcoverage areas

Typical photos ofCT samples during the process of fatigue crack growth test

Morphologies of the fatigue crack initiation region onthe notched samplessubjected tomultiple laser peening impacts

Crack block and fatigue strip in fatigue fracture under differentlaser peening coverage areas

5. Laser peen forming

Principle and typical forming sample of laser peen forming

Prism surface Arc surface

Application of laser peen forming technology

Theory and technology of laser driven flyer micro plastic forming