1.Finite Element Analysis of Damage Mechanism of Composite Structures under High and Low Velocity Impact.In order to reduce the structural weight and increase the flexibility of the aircraft, laminated composites have been widely used in theaerospace industry because of their high performance-weight ratio. However, poor out-of-plane properties, low damage tolerance and low delamination resistance have significantly restricted their applications inprimary-loading components.Delamination is the main damage mechanism of laminated composites under impact loading, which can cause obvious degradation of the material mechanical properties. In recent years,3Dbraided composites have received much attentiondue to theirexcellentadvantagesover the laminated composites. The distinct feature of 3D braided composites is anintegrated near-net-shape structure to provideoutstandingthrough-thickness propertiesandprevent delamination under ballistic impact loading. Owing to these prominentmerits,3D braided compositesare believed to havebroad potential applications inmilitaryaircrafts, armor vehicles and protective structures.

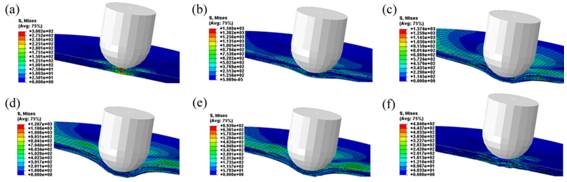

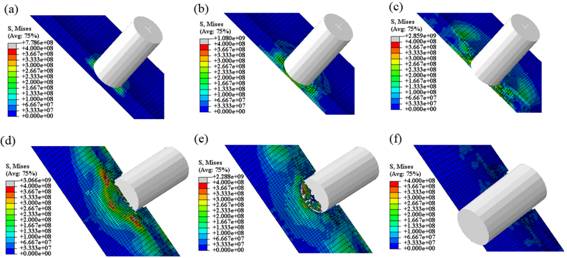

Fig. 1 Low velocity impact process of cross-ply composite laminates under certain impact energy (a)t= 0.05 ms (b)t = 0.7 ms (c)t= 1.4 ms (d)t= 2.1 ms (e)t= 3.5ms (f)t= 5.0 ms

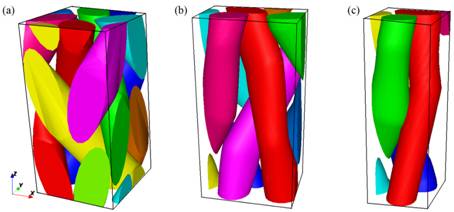

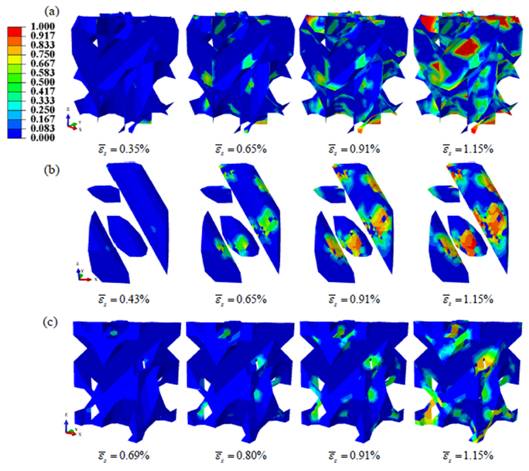

Fig. 2 Ballistic penetration process of the flat projectile in the 3D braided composite target plate (a)t=1µs (b)t=3µs (c)t=6µs (d)t=8µs (e)t=11µs (f)t=40µs Physical impact experiments are expensive, time-consuming, and confined to certain structural parameters and certain impact conditions.However, lesslimitationexists in the impact simulation by usingfinite element method. Thus, we employ finite elementmodeling methodto study the impact damage behavior of composite structures, as shown in Fig. 1 and Fig. 2. 2. Meso-scale Finite Element Analysis of Mechanical Behavior of 3D Braided Composites Subjected to Different loading cases.Owing to the good structural periodicity of 3D braided composites, the meso-scale finite element model (FEM) is commonly used to predict the mechanical properties by establishing a periodic representative volume element (RVE) or a unit-cell model. Generally, the route of meso-scale FEM is as follows: (1) Analyze the meso-structure of material and create a suitable unit-cell model, (2) Establish the appropriate constitutive relations of constituents, (3) Impose reasonable periodic boundary conditions and investigate the mechanical response of the unit-cell structure, (4) Predict the macro-mechanical properties of the composite material by homogenization approach. By using meso-scale FEM, not only the overall properties of the composite material but also the damage characteristics and failure modes, can be obtained and analyzed. Consequently, meso-scale FEM is considered as the most economical and effective numerical method to study the mechanical behavior of 3D braided composites. In this field, we have published many high level papers,including the establishment of microstructure models, the prediction of stiffness and strength properties, and the investigation of damage and failuremechanismsunder various loading cases, as displayed in Fig. 3 and Fig. 4. By the way, we will apply for two new research projects in this field in 2018. 3. Extended Finite Element Method (XFEM) for Fracture Analysis of Composite Structures.This is a new research field for my visiting in University of Sheffield in UK.

Fig. 3 Structure models of three different unit-cells (a) Interior unit-cell (b) Surface unit-cell (c) Corner unit-cell

Fig. 4Damage evolution process of unit-cell of 3D braided composites underdifferentaxial strains(a)Interface debonding(b)YarnLTtensile shearfailure(c)Matrix cracking |

[1] Zhang Chao*, Duodu Enock A, Gu Jinan. Finite element modeling of damage development in cross-ply composite laminates subjected to low velocity impact. Composite Structures, 2017, 173: 219-227. (SCI: 000402212700025) [2] Zhang Chao*, Curiel-Sosa Jose L, Duodu Enock A. Finite element analysis of the damage mechanism of 3D braided composites under high-velocity impact. Journal of Materials Science, 2017, 52: 4658-4674. (SCI: 000395103200045) [3] Zhang Chao*, Curiel-Sosa Jose L, Bui Tinh Quoc. A novel interface constitutive model for prediction of stiffness and strength in 3D braided composites. Composite Structures, 2017, 163: 32-43. (SCI: 000393931800004) [4] Zhang Chao*, Curiel-Sosa J L, Bui T Q. Comparison of periodic mesh and free mesh on the mechanical properties prediction of 3D braided composites. Composite Structures, 2017, 159: 667-676. (SCI: 000386759100063) [5] Zhang Chao*, Mao Chunjian, ZhouYexin. Meso-scale damage simulation of 3D braided composites under quasi-static axial tension. Applied Composite Materials, 2017, 24: 1179-1199. (SCI: 000412067300011) [6] Zhang Chao*, Xu Xiwu. Finite element analysis of 3D braided composites based on three unit-cell models. Composite Structures, 2013, 98: 130-142. (SCI: 000315001100015) [7] Zhang Chao, Xu Xiwu*, Chen Kang. Application of three unit-cells models on mechanical analysis of 3D five-directional and full five-directional braided composites. Applied Composite Materials, 2013, 20(5): 803-825. (SCI, 000325617300005) [8] Zhang Chao, Zhou Yexin, Yang Zhixian, et al. Numerical analysis on interface damage mechanisms of 3D braided composites. Acta Materiae Compositae Sinica, 2016, 33(9): 1989-1998. (EI index) [9] Zhang Chao, Xu, Xiwu , Xu, Xiaojing. Research progress in finite element analysis on macro-meso mechanical properties of 3D multi-directional braided composites. Acta Materiae Compositae Sinica, 2015, 32(5): 1241-1251.(EI: 20154601529084) [10] Zhang Chao, Xu Xiwu, Chen Kang. Damage mechanism analysis of 2D braided composites under unidirectional tension. Transactions of Nanjing University of Aeronautics & Astronautics, 2013, 30(4): 317-327. (EI index) [11] Zhang Chao, Xu, Xiwu, Yan, Xue. General periodic boundary conditions and their application to micromechanical finite element analysis of textile composites. Acta Aeronautica et Astronautica Sinica, 2013, 34(7): 1636-1645.(EI: 20133416646551) [12] Zhang Chao, Xu, Xiwu, Yan, Xue.Three unit-cell structure models of 3D five-directional braided composites.Transactions of Nanjing University of Aeronautics & Astronautics, 2013, 45(2): 170-178. [13] Zhang Chao, Xu, XiWu, Guo, Shuxiang. Damage and failure mechanism analysis of 3D five-directional braided composites with interface debonding under unidirectional tension. Journal of Aeronautical Materials, 2011, 31(6): 73-80.(EI: 20115214639156) [14] Zhang Chao, Xu, Xiwu Mao, Chunjian. Progressive damage simulation and strength prediction of 3D braided composites. Acta Materiae Compositae Sinica, 2011, 28(2): 222-230.(EI: 20112114007009) [15] Zhang Chao, Xu Xiwu, Guo, Shuxiang. Microstructure model and finite element analysis of mechanical properties of 2D 1×1 biaxial braided composites. Acta Materiae Compositae Sinica, 2011, 28(6): 215-222. (EI index) [16] Zhang Chao, Xu Xiwu. Geometrical model and elastic properties prediction of 2D biaxial braided composites. Acta Materiae Compositae Sinica, 2010, 27(5): 129-135. (EI index) |