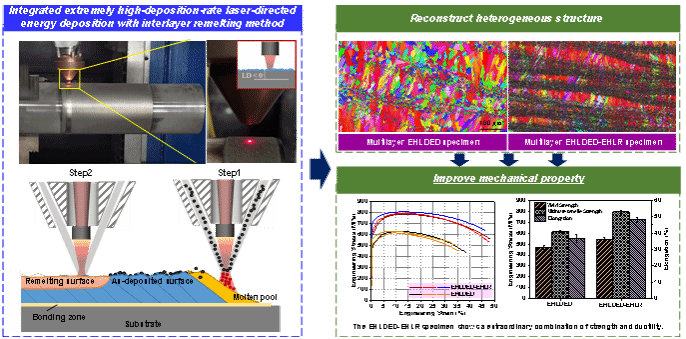

Recently, Professor Lu Jinzhong and Professor Luo Kaiyu from the School of Mechanical Engineering at our university have developed a novel ultra-high-speed laser hybrid additive manufacturing technology (EHLDED-EHLR). This technology significantly promotes the transition from columnar crystals to equiaxed crystals during the solidification process, forming a spatially heterogeneous structure dominated by ultra-fine equiaxed crystals. As a result, both the strength and ductility of the material are simultaneously improved. The relevant research findings have been published in the top journal of the mechanical manufacturing field, International Journal of Machine Tools and Manufacture (IF=14), with the title "High-performance functional coatings manufactured by integrated extremely high-speed-rate laser directed energy deposition with interlayer remelting."

Ultra-high-speed laser directed energy deposition technology has garnered widespread attention due to its excellent processing efficiency. However, the challenges of controlling surface roughness and suppressing internal defects have limited the preparation of customized thickness deposition layers. To address this issue, the research team proposed a novel ultra-high-speed laser hybrid additive manufacturing technology, which simultaneously introduces interlayer ultra-high-speed laser remelting during the ultra-high-speed laser directed energy deposition process. This approach reduces surface roughness by 57% and decreases porosity by 67%, resulting in a typical spatially heterogeneous structure dominated by ultra-fine equiaxed crystals. Consequently, the tensile strength and elongation of 316L stainless steel are improved by 24.52% and 28.95%, respectively.

The research work has been funded by the National Key Research and Development Program of China (2022YFB4600500) and the Jiangsu Provincial Science and Technology Plan Project (BE2022069-4). Young teacher Xu Xiang is the first author of the paper, while Professor Lu Jinzhong and Professor Luo Kaiyu serve as co-corresponding authos.

Original link: https://doi.org/10.1016/j.ijmachtools.2024.104174.